Image credit: https://zortrax.com/wp-content/uploads/2016/02/Zortrax_M200_workshop.jpg

3D printers can be used as a revolutionary teaching tool to engage pupils, and they can help students to understand design and manufacturing and learn hands-on. However, with so many different types of machine, filament and software packages to choose from, how do you decide what will work best for you and your students?

Here are our top 10 questions to think about when choosing a printer:

1.How much do you want to pay?

3D printers range in price from a few hundred pounds to tens of thousands of pounds. Generally speaking, you will pay more for advanced 3D printing technologies such as stereolithography. The most cost-effective 3D printers are Fused Filament Fabrication (FFF) units and these are the most common ones found in the classroom at the moment.

Looking beyond the initial cost, it’s also important to consider the cost of replacement parts. Some printers require new nozzles every few months and some perform better with a fresh print bed after the same period. FFF 3D printers may also require new Bowden tubes. You should also consider support services; some manufacturers require that any support goes through them, rather than the supplier.

2.What size objects do you want to print?

3D printers can have a build size of less than 100 cubic inches (an example being the Makerbot Replicator Mini) or a build volume exceeding 400,000cm³ (an example being the 3DP Workbench). The bigger the build size the bigger the models you can print.

3.How easy should it be to use?

Some 3D printers are easier to use than others. Some can be plugged into the wall and run almost immediately, while others require a strict setup process to take place.

Another important consideration with regards to this is connectivity, because it’s simpler to send files to print over Wi-Fi than with a USB stick or SD card.

4.What materials can it print with?

Most Fused Filament Fabrication 3D printers will print with ABS or PLA, while others will also print with nylon. However, if a 3D printer does not have a heated print bed then it will only be able to print with PLA. ABS and PLA both have their place when it comes to 3D printing.

5.How reliable is the machine?

Just as cars have different reliability scores so do 3D printers. Most desktop printers are reliable nowadays, although some manufacturers do make their printers with better quality mechatronics and components than others.

All 3D printers come with a limited manufacturer’s warranty. The standard warranty offered usually covers your 3D printer for 12-months. However, these warranties do differ wildly, so it is worth considering what you want from your warranty.

There are certain manufacturers, for instance, who do not let resellers or suppliers diagnose and repair their 3D printers, while there are other manufacturers who want nothing to do with the warranty process and let resellers and suppliers handle all of the work. You need to know which of these applies to you, so that you know who you need to call in the event that you experience issues with your 3D printer.

6. How accurate do you need the prints be?

Some 3D printers are not as accurate as others. Can the printer produce objects that are true to a CAD model? For example, if a student’s 3D printed snap-fit part doesn’t go together, where does the fault lie? With the student or the printer?

7. What safety features do I need?

3D printers have moving parts, and you may wish to buy a printer with a surround so as to prevent students from touch the device when in use.

Another important safety feature is a High Efficiency Particulate Air (HEPA) filter. These filters filter the air before it leaves the 3D printer.

Image credit: https://zortrax.com/wp-content/uploads/2016/01/14.jpg

8. What software can I use?

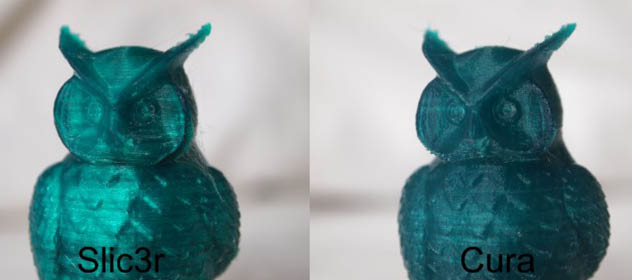

Some 3D printer manufacturers include slicing software with their printers (for example, Ultimaker ships with Cura). However, you can actually use whatever slicing software you like with a 3D printer providing it is compatible. The important thing to bear in mind with slicing software is that this software can determine the quality of prints.

For example, here’s a side-by-side comparison of two parts printed with different programs:

Some slicing programs also work better with certain 3D printers.

9. Where will it be located?

The environment that a 3D printer operates within is a very important consideration. Depending on the unit that you choose, a change in temperature (draft, air conditioning) can affect the print quality. It will also need to be within reach of a reliable power supply.

In addition to this, you need to consider health and safety. The 3D printer must not under any circumstances present a danger to students. The biggest danger comes from the printer’s moving parts where hair or clothing could become trapped. The obvious solution to this is to have an enclosed machine or keep in an area of the room when it is out of the way from student traffic.

10. How will you learn how to use the printer?

It goes without saying that everybody who’s going to use your 3D printer needs to know the basics, such as how the machine accepts files, how the 3D printing process is started, what any notification lights mean and how to pause and resume printing.

It is possible to learn these things from the user manual and through trial and error, although it is a lot easier and faster to invest in training. Training can usually be offered by your supplier at the time of installation, however you should make sure that the training being offered covers everything you need to know about your 3D printer.

Lastly, keep in mind these three things…

1.3D Printers are not ‘plug and play’

Don’t believe what anybody has told you; there isn’t a single 3D printer on the market that is truly ‘plug and play’. You will have to spend some time with your 3D printer before you can make the most of it. So don’t expect to take your 3D printer out of the box and get started printing right away. 3D printers are not the same as paper printers. So please do go into your research with an open mind with a view to investing time into your 3D printer.

2.A single choice technology will not fulfil all of your requirements!

There’s a reason there are so many different additive manufacturing technologies – they all offer different things! And so, a single technology will not fulfil all of your requirements.

If you want to fulfil 100 per cent of your requirements, then you are going to need to invest in several different 3D printers, comprising Stereolithography printers such as the Formlabs Form 2, Fused Filament Fabrication printers such as the Zortrax Inventure and maybe even a Composite Filament Fabrication printer such as the Mark Two.

3.3D printing is the end of the journey (CAD is the real learning tool)

Last but not least, 3D printing is the end product of the design journey. It gives you the tangible and measurement part of the journey only – a physical object that you can assess and grade. The real learning tool for students is the CAD software they will use. To this end, pupils will learn more by using several different CAD software programs instead of just one, so long as the software comprises traditional CAD and freeform modelling tools.

So when you are looking at 3D printers to purchase, don’t forget to consider the software tools that pupils will be using to design their 3D models.

To help you figure out what’s important to you, watch this video of Kevin Askew from GoPrint3D, talking to teachers and technicians at the recent 3D printing course run by the National STEM Learning Centre: